Case study & Key takeaways

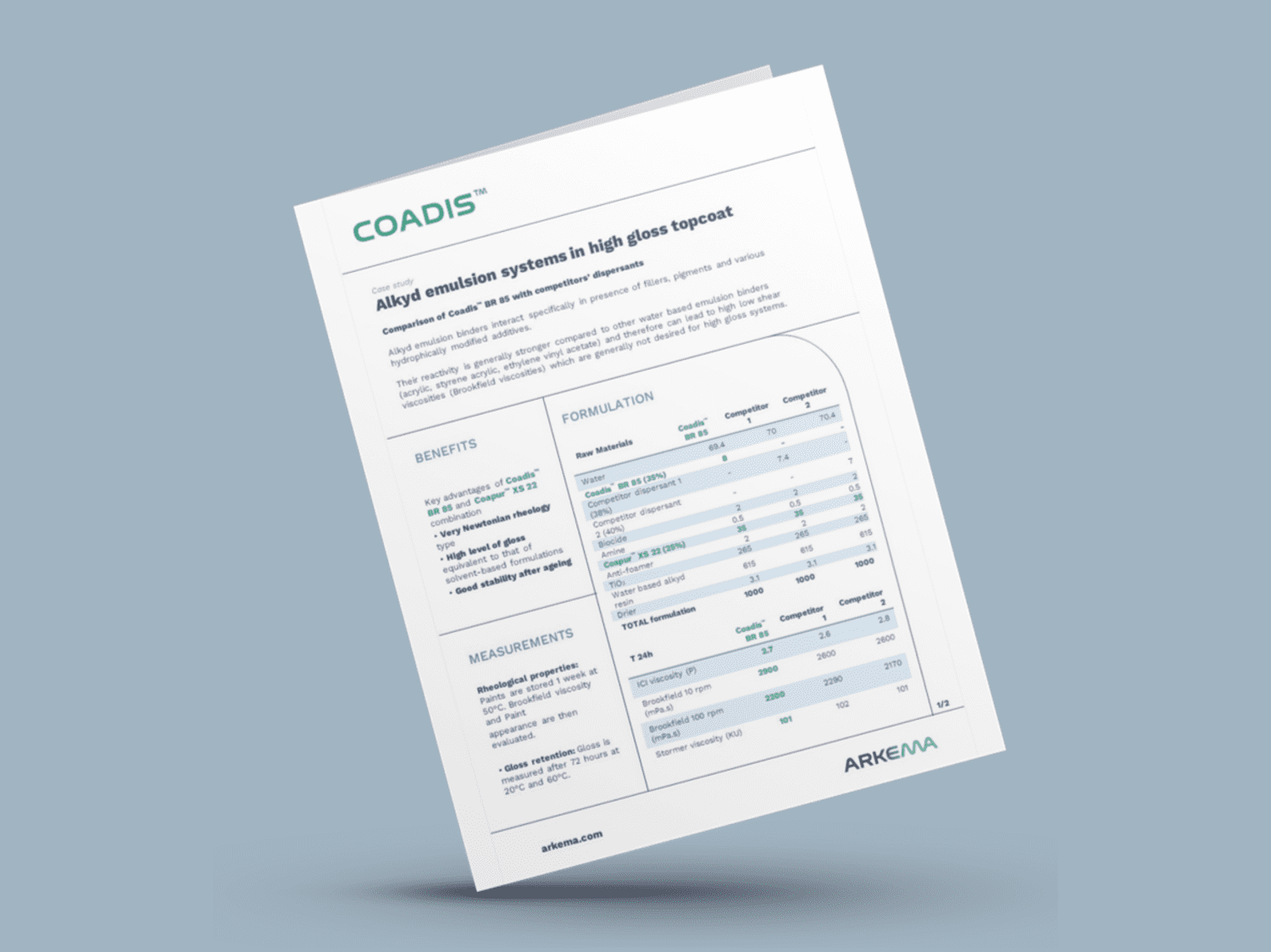

Alkyd emulsion binders interact specifically in presence of fillers, pigments and various hydrophically modified additives.

Their reactivity is generally stronger compared to other water based emulsion binders

(acrylic, styrene acrylic, ethylene vinyl acetate) and therefore can lead to high low shear

viscosities (Brookfield viscosities) which are generally not desired for high gloss systems.

Key advantages of Coadis™ BR 85 and Coapur™ XS 22 combination

- Very Newtonian rheology type

- High level of gloss equivalent to that of solvent-based formulations

- Good stability after ageing

Key takeaways:

Comparison of Coadis™ BR 85 with competitors’ dispersants

- Viscosity evolution after 1 week @50°C

- Paint appearance after 1 week @50°C

- Gloss after 72 hours

Find out more...

-

ALKYD EMULSION SYSTEMS

The document has been added to your favorites

You can add your own notes to this document

Select, compare & order your products

PRODUCT SELECTOR

Contact us

See also

Back to all articles- Webinar

Sustainable transformation of the coatings industry through flagship solutions

Jun 7, 2024

- Expertise articles

Challenges, trends and opportunities facing the coatings industry when it comes to the topic of sustainability

Sep 2, 2024

- Expertise articles

Sustainability Drives Innovation at Arkema

Sep 2, 2024